湿法压膜技术源于美国杜邦集团,此技术的诞生,提高了传统印刷精细线路开、短路的良率以及提高生产效率。杜邦公司经过多年的科研,最终开发出了能与水进行良好化学反应的干膜,如:SD200系列、ST900系列、FX900系列等多种类多用途的干膜。

杜邦湿法压膜应用领域:

随着市场环境的改变,杜邦湿法压膜技术的应用也得到了广泛的推广,目前湿法压膜技术在PCB、FPC、ITO(触摸屏)与五金蚀刻方面得到了广泛的应用,根据杜邦中国集团公司统计的数在2010年全国装有杜邦湿法系统的设备一共238套,2012年底全国共装有374套。

杜邦湿法贴膜的优点:

1、 使粗糙的铜表面得到完整的压膜效果,大幅降低了开、短路引起的不良;

2、 使铜面与干膜的结合力更好;

3、 制作的线路比干压更为精细。

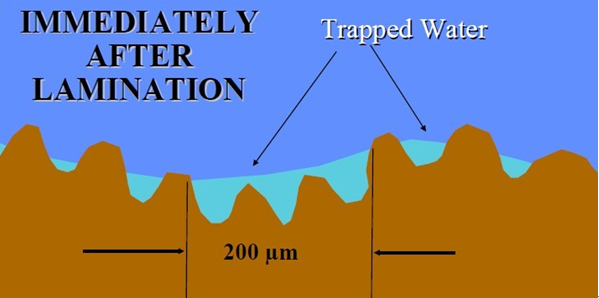

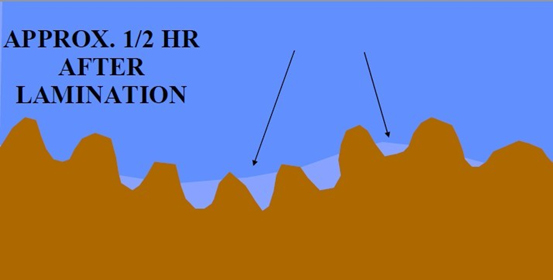

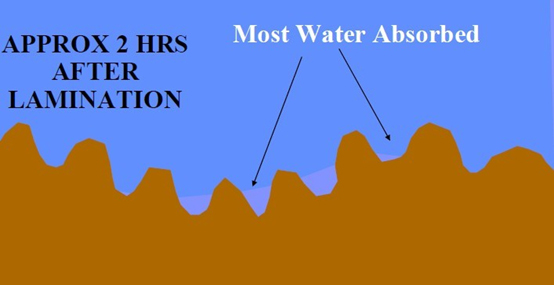

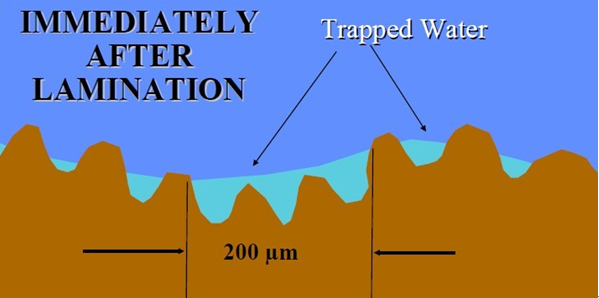

湿法压膜干膜与水反应示意图:

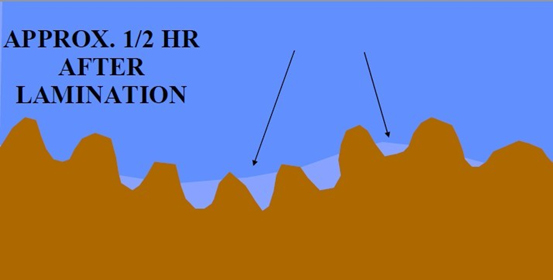

图1:压好干膜的板材经过放大之后会看到板面凹坑内部原来的空气经过湿法压膜后变为了积水

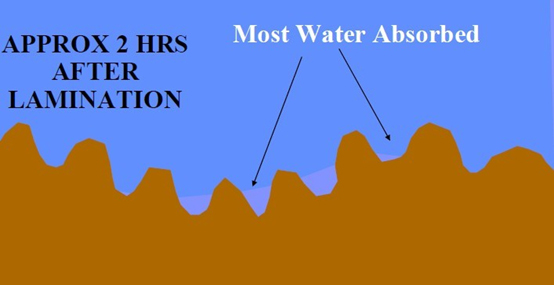

图2:经过静止一段时间后可以看到干膜逐步与水进行化学反应,干膜逐步渗入凹坑

图3:经过长时间的静止发现干膜已经全部融入凹坑

注:经过浸水的铜面,可以加速与干膜的反应,将铜面上粗糙地方的气体赶走且使干膜本身软化而更有粘性,与铜面的结合力更紧密,并可以对铜面上的凹坑及划伤有很大的填充作用。

杜邦湿法压膜的发展:

杜邦中国集团公司作为干膜业内的领头羊,多年来一直投入大量资金研发新产品。关于杜邦湿法压膜,杜邦集团公司科技实验室已经着手开始研发第二代湿法压膜系统,此系统目前在部分客户处做生产测试。根据了解到的信息,第二代杜邦湿法压膜系统会大幅度的降低板面因灰尘、擦伤、凹凸不平等造成的开、短路。

The wet lamination technology originated from DuPont Group in the U.S. This technology was created to improve the yield of traditional printing fine lines open and short as well as improve production efficiency. After years of scientific research, DuPont finally developed dry films that can react well with water chemically, such as: SD200 series, ST900 series, FX900 series and other multi-purpose dry films.

DuPont wet lamination applications:

With the change of market environment, the application of DuPont wet lamination technology has also been widely promoted. At present, wet lamination technology is widely used in PCB, FPC, ITO (touch screen) and hardware etching, according to the statistics of DuPont China group of companies, there were 238 sets of equipment equipped with DuPont wet lamination system in 2010 and 374 sets at the end of 2012.

Advantages of DuPont wet lamination:

1、so that the rough copper surface to get a complete pressure film effect, significantly reduce the open, short circuit caused by bad

2、Better bonding of copper surface to dry film

3、The production line is more delicate than dry pressing

Schematic diagram of the reaction between wet pressed dry film and water:

Figure 1: After the magnification of the pressed dry film, you can see that the original air inside the crater of the board surface has become water after the wet lamination.

Figure 2: After a period of resting, you can see that the dry film gradually reacts with water chemically and the dry film gradually penetrates into the pits.

Figure 3: After a long time of resting, it is found that the dry film has been fully integrated into the crater.

Note: After dipping the copper surface, it can accelerate the reaction with the dry film, drive away the gas from the rough places on the copper surface and make the dry film itself soften and stickier, and the bonding force with the copper surface is closer, and it can have a great filling effect on the pits and scratches on the copper surface.

The development of DuPont wet lamination:

As a leader in the dry film industry, DuPont China Group has been investing heavily in research and development of new products for many years. Regarding DuPont wet lamination, DuPont Group's Science and Technology Laboratory has started to develop the second generation of wet lamination system, which is currently in production testing at some customers. According to the information learned, the second generation of DuPont wet lamination system will significantly reduce the open and short circuit caused by dust, scuffing, unevenness, etc. on the board surface.